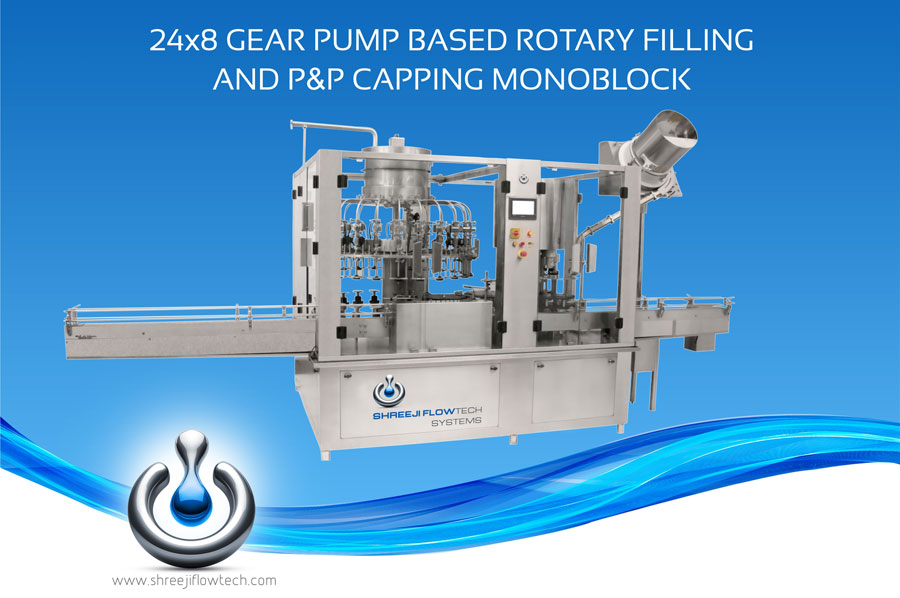

24 Head Rotary Filling Machine & 8 Head Pick and Place Capping Machine Monoblock

- Download Brochure

Details - 24 Head Rotary Liquid Filling Machine & 8 Head Pick and Place Capping Machine

Gear Pump Filling and capper mono block offers flexibility for wide range of liquids with ease of simply. Gear pump fillers are positive displacement pumps with self-priming features. Pumps can fill minimum to maximum fill volume without any mechanical setting by HMI such as a flow meter. Gear Pump filling is a cheaper option of flow meter filling.

Gear Pump Filler is accurately measured the revolutions of the pump and motor assembly. Fill rates can be modulated controlling the motor RPM and running time with guaranteed to result in a clean end to your fill cycle.

Specifications

-

7” color touch screen with plc for various error message and control system

-

Rugged, Reliable construction

-

Cam operated bottle lift mechanisms for reliability and long life

-

In feed screw, star, main star, and exit star wheels precisely align each bottle

-

Motorized height adjustment of capping turret

-

No bottle no filling, no bottle no cap release, Outfeed jam machine stop, low cap in maxine machine stop, Auto feeder on/off system, Safety door open machine stop

-

24V BLDC motor operated gear pump

-

Pick n place cap transfer to the capping head

-

Maintenance free pneumatic gripper type capping head

-

Cap feeder auto on/off system preventing cap damage

-

Cappers include fully adjustable cap torqueing head for precise torque control

-

Programmable for multi speed and profile filling cycles

-

Designed for easy change-over and cleaning

-

Integrated fault light and alarm to inform operator production error

-

Individual nozzle fill volume adjustment by HMI

-

Synchronized variable speed control

-

All contact parts are SS-316/peek/PTFE/silicon/EPDM and non-contact parts SS 304, MS frame structure with SS cladding

-

Precise filling valve for 100% spillage/drip free on bottle neck and shoulder

-

Fully interlocked guarding for machine protection safety

-

High filling accuracy: ±1%

-

CIP at temperatures up to 70°c

Images & Links of Liquid Filling Machine for Different type of Bottles

4 Head Servo Based Piston Filling Machine

Six Head Servo Based Piston Filling Machine

8 Head Gear Pump/Flow Meter Based Inline/Linear Filling Machine

8 Head Servo Based Piston Filling Machine

12+12 Head Servo Based Piston Filling Machine

16 Head Flow Meter Based Rotary Filling and 8 Head P&P Capping Machine

24 Head Gear Pump Based Rotary Filling and 8 Head P and P Capping Monoblock

30 Head Flow Meter Based Rotary Filling with 12 Head ROPP Capping Machinery