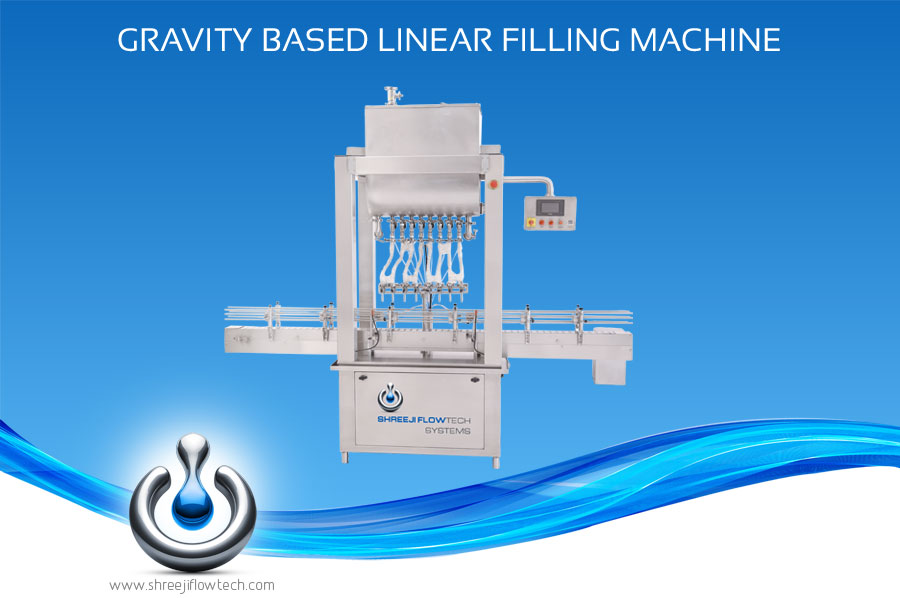

Gravity based Liquid Filling Machine for Bottles

- Download Brochure

Details - Gravity based Liquid Filling Machine

The gravity based filling is suitable for Water, solvents, alcohol, specialty chemicals, paint, inks, corrosive chemicals i.e. acids and bleach.

This type of filler is best suited for liquids with very thin viscosities that do not change with ambient temperature or with batch variation. Balance tank with continuous liquid circulation from main tank to maintain constant liquid level.

Each filling valve is independently timed by the HMI so that precise amounts of liquid will flow by gravity into the container. Gravity fillers built with bottom up fill capability can handle a wide range of free flow type liquids.

Specifications - Gravity based Linear Liquid Filling Machine

-

7” color touch screen with plc for various error message and control system

-

Rugged, reliable construction.

-

No bottle no filling, Out-feed jam machine stop

-

Safety door open machine stop,

-

Timing Valve on each filling head

-

Precise filling valve for100% spillage/drip free on bottle neck and shoulder

-

High filling accuracy: ± 2 to3 %

-

CIP at temperatures up to 80°c

-

Smooth and accurate container handling

-

Fully interlocked guarding for machine protection safety

-

Programmable for multi speed and profile filling cycles

-

Designed for easy change-over and cleaning

-

Integrated fault light and alarm to inform operator production error

-

Individual nozzle fill volume adjustment by HMI

-

Synchronized variable speed control

-

All contact parts are SS 316/peek/PTFE/silicon/Viton and non-contact parts SS 304, MS frame structure with SS cladding

-

Lifetime pre lubricated gear motor for Main drive

-

Tool less adjustable conveyor guide rails to accommodate with different products

Images & Links of Liquid Filling Machine for Different type of Bottles

4 Head Servo Based Piston Filling Machine

Six Head Servo Based Piston Filling Machine

8 Head Gear Pump/Flow Meter Based Inline/Linear Filling Machine

8 Head Servo Based Piston Filling Machine

12+12 Head Servo Based Piston Filling Machine

16 Head Flow Meter Based Rotary Filling and 8 Head P&P Capping Machine

24 Head Gear Pump Based Rotary Filling and 8 Head P and P Capping Monoblock

30 Head Flow Meter Based Rotary Filling with 12 Head ROPP Capping Machinery